Offering excellent services, our commitment!

- RECEIPT of the quotation request

- Sending BUDGET in 24H

- MOLD MANUFACTURE

- Sending TEST parts to the customer

- PROJECT Development

- Sending production PLANNING to the customer

- Quality CONTROL Check

- MOLD SHIPMENT

- RECEIPT of the quotation request

- Sending BUDGET in 24H

- PROJECT Development

- Sending production PLANNING to the customer

- MOLD MANUFACTURE

- Sending TEST parts to the customer

- Quality CONTROL Check

- MOLD SHIPMENT

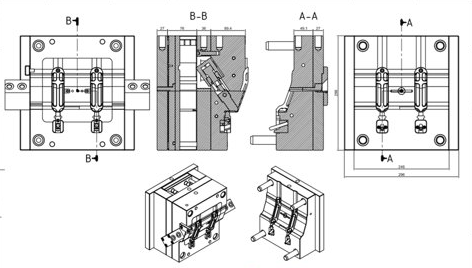

Technical Molds

We manufacture technical molds for the plastic injection industry following a rigorous technical specification, using several technical solutions, which stands out:

- Micro hot runner on piece;

- Valve hot runner in transparent materials;

- Standard structures;

- Individual molding elements;

- Real-time mold manufacturing planning, supported by specific software;

Project Office

Project management is done by specialized professionals who follow the best conduct, use advanced management tools and the latest CAD/CAM/CAE technologies.

Team that privileges communication throughout the process with the provision of periodic reports.

Production Capacity

FactorMill has the capacity to develop projects up to 10 molds simultaneously, in a short period of time, and to produce annually about 40 to 50 molds with high dimensional accuracy whose weights vary between 15 Kg and 1500 Kg and with a machining capacity of 700 x 500 mm.

Technology

- 2 Programming stations

- 3 CNC machining centers 700mmx500mm

- 1 High-speed CNC machining center 500mmx300 mm

- Electro-erosion Penetration

- CNC 700mmx500mm (ONA QX4)

- 1 Electro-erosion CNC Wire-Cut 700mmx500mm (ONA AF35)

- 1 Electro-erosion CNC penetration 500mmx300mm

- 1 Laser Welding Machine

- 1 Flat Rectifier

- 1 Conventional Lathe

- 1 Drill

- 1 Frosting Machine

- Various support machines